|

CYG Changtong New Material Co,,Ltd.

|

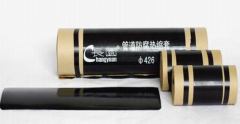

Polyethylene Anticorrosion Tapes for pipeline

| Price: | 5.0~6.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The installed product provides outstanding adhesion and elastic properties.Excellent anti-aging and UV resistance properties.

Polyethylene Anticorrosion Tapes are made from a polyethylene and butyl rubber. The installed product provides outstanding adhesion and elastic properties. They are highly adaptive to forces caused by changes in temperature and soil stress creep. They have excellent anti-aging and UV resistance properties.

Specifications

Polyethylene Anticorrosion Tapes for oil,gas,petrochemical, waste water underground and overhead pipelines. The tape shall be applied after the liquid adhensive by hand or with the wrapping mathine.

Resistant to UV

Excellent adhension to pipe and itself

Excellent resistance to cathodic disbonding

Good conformability and sonsistant uniform thickness

Meet ASTM D 1000 standard

Features:

The thickness of the tape ranges from 0.4mm to 1.3mm; the backing thickness ranges from 0.25 to 0.8mm and the adhesive thickness ranges from 0.1 to 0.9mm.

The tape can be used in wide range of temperature: -30℃~80℃.

Good anticorrosion, the tape also enjoys crashworthiness.

Long durability, the tape can be used for 30 years.

Wide application, the tape is suitable for the pipe from 50mm to 1800mm

Repair of pipelines, storage tanks and irregular shapes like flanges, tees, bends, elbows etc.

Cold adhesive tape includes three parts: anticorrosion tape, protective tape, repair tape

Product performance:

item | Anticorrosion tape | Test method |

Tensile strength | ≥18MPa | GB1040 |

Yield strength | ≥15MPa | GB1040 |

Elongation | ≥20% | GB1040 |

Peel strength | ||

To primed steel plate | ≥25N/cm | GB2792 |

To back material | 5~10N/cm | GB2792 |

Dielectric strength | ≥30Mv/m | GB1408 |

Volume resistivity | ≥1*1012Ω*m | GB1410 |

Water absorption | ≤0.1% | SY0414 |

Vapor permeability | ≤0.2mg/cm³ | GB1037 |

Applicable temperature | 5~50℃ | |

Color | Black |

Installation

1 General Provisions:

1.1 The installation of anti-corrosion layer should carry out in the temperature 3℃ higher than leak point temperature.

1.2 Primer and adhesive tape should not be applied in sandy situation when there is no reliable protective measure.

2Winding adhesive tape

2.1 The temperature to unwind adhesive tape should be above 5℃.

2.2 In winding, adhesive tape can be used together with primer and those fillers which are compatible with adhesive tape for filling the two sides of weld joints.

2.3 Use appropriate mechanical or hand tools. Painting primer firstly and winding adhesive tape following. The lap length of the starting end and the end of adhesive tape should not less than 1/4 steel pipe circumferential length and should not less than 100mm. The overlapping parts of inner tape and outer tape should be staggered. In winding, the edge of adhesive tape should be parallel, no twist or wrinkle at all.

2.4 In winding adhesive tape in factory, cold adhesive tape can be used directly or after heating. When winding anticorrosion tape, 150mm±10mm weld part should be reserved.

2.5 In winding irregular shaped pipe, repair tape should be a choice, or other special adhesive tape which is better than repair tape in performance. The demand for surface treatment and primer paint of irregular shaped pipe is same as pipe body.

Notice: 1 The number of stacked layers of preformed anticorrosive tubes should follow the principle of "NO DAMAGE TO ANTICORROSIVE LAYER". Different kinds of finished pipe should be stacked separately and soft objects should be placed between anticorrosion pipe layer and at the bottom part to prevent any damage from anticorrosion layer.

2. When load and unload anticorrosion pipe, wide nylon belt or dedicated spreader should be used. Throwing, touching and prying anticorrosion layer are forbidden.

3. Adhesive tape should be stored in a cool and dry place. Avoiding direct sunlight and keeping it away from heat and fire source. It had better be stored in -20~30 ℃.

Related Search

Polyethylene

Tapes

Density Polyethylene

Polyethylene Pipe

Polyethylene Glycol

Polyethylene Hdpe

More>>

.gif)